Note: This DIY article is provided as a general guide only and is not intended to take the place of product-specific installation procedures; always follow applicable manufacturers’ instructions. Depending on your home’s age and condition, location within the home, and other potential factors, repairs and/or upgrades or other services may be necessary prior to the beginning and/or completion of your project that may involve the services of a home improvement professional. This article does not include advice pertaining to local building codes and/or any related inspections.

Remember when your heart didn’t skip a beat every time you saw the electricity bill? What if you learned that one of the reasons for your expensive energy bills is the lack of an electrical outlet insulation seal in your home? Read on to learn how sealing a few outlets can keep money in your pocket and make your home comfortable (among other benefits).

The most effective outlet insulation method is applying sealant to the gaps and cracks. However, you may also use electrical outlet gasket seals.

Understanding outlet insulation: The problem

You’re probably wondering, “What’s with all the fuss surrounding a few light switches and electrical sockets?” and “Can you make any significant savings from simply insulating these small gaps on the wall?” To properly understand the answers to these questions, you must first understand the problems of allowing sneaky drafts into your home.

Drafts and air leakage

Nothing beats the feeling of walking into your perfectly cooled home during a summer heat wave (or coming home to a warm and toasty home on a snow day). It’s a convenience you know all too well, and one you might already be paying a pretty penny to enjoy. Therefore, it goes without saying that any unwanted drafts will negatively impact your comfort at home.

Whether it’s a stream of hot air in the middle of summer or a chilly draft during winter, drafts are unwelcome. This is one of the reasons why houses without electrical outlet insulation can prove to be inhospitable.

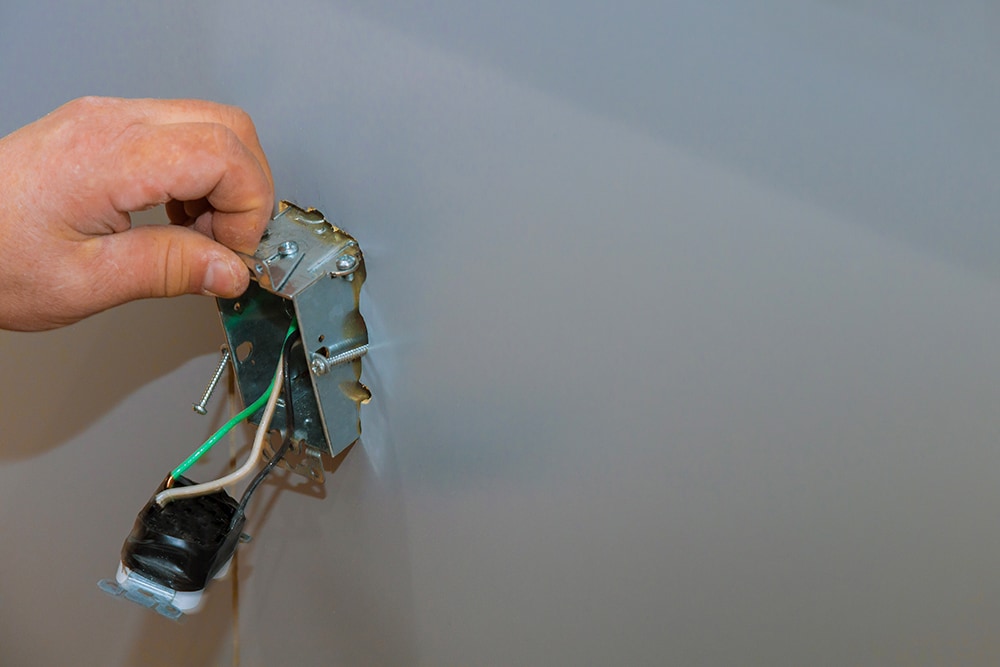

Spray foam is applied around the electrical box (not inside) to ensure an airtight seal that ensures your HVAC unit doesn’t work overtime to achieve optimum temperature.

Increased energy costs

When the conversation around energy costs switches to opportunity cost, there is a lot you can do with the money you might be paying to keep your home’s temperature just right. The drafts and air leakage mentioned earlier will probably have you cranking up the AC, which means an added workload on your HVAC system that, in turn, translates to more expensive energy costs.

Simply put, you don’t have to pay more than you have to just to keep your indoor temperatures within the optimum range, and investing in a high-quality insulating foam for outlet insulation could be the first step toward realizing significant savings.

Loss of home comfort

The financial impact might be what hurts the most, but sweating into your eyes in the middle of a heatwave could be the last straw that makes you look for electrical outlet insulation. Rooms without proper insulation might feel warmer in the summer and cooler in the winter, making it difficult to achieve an ideal temperature.

Why proper insulation for outlets is critical

Once you understand the problems associated with leaky electrical outlets, you become aware of the benefits of investing in a quality seal to help solve your draft problem. Outlet insulation works hand in hand with your wall’s insulation to create an effective thermal barrier.

Proper insulation for outlets enables you to ensure your home attains optimum temperature ranges regardless of the prevailing weather conditions in the most efficient way possible. It also doesn’t hurt that you get to save a bit of money along the way.

Choosing the right electrical outlet insulation seal

In the world of construction, not all seals are made equal. Investing in premium quality for your sealing needs ensures you don’t have to carry out maintenance every time the wind blows. If having a sealant that lasts as long as the surfaces it is bonded to sounds like something you’d like, then keep reading to understand why GE sealants are exactly what you need.

Weatherproofing

Your electrical outlets sneak in drafts and air leaks because they open a line of communication between the indoor and outdoor spaces. Consequently, when choosing a seal to plug the leak, you should choose one that effectively forms a barrier between the two spaces.

Cutting corners is not a great idea when working with electrical outlets. High-quality spray foam sealant is UV-resistant and can withstand a wide temperature range, ensuring it retains its integrity through the seasons.

Flexibility

An outlet insulator must expand to fill the space, preventing the draft from flowing into your home. High-quality spray foam will enable you to do just that while allowing you to rest assured that your repair project will not be subjected to warping or bowing. Flexibility also guarantees that the adhesive moves with the surface it is bound to, ensuring a long-lasting seal.

Pest control

Yes, the sealant’s barrier will keep draft and moisture out of your home. But what about the ants you might have seen surrounding the sugar tin in your kitchen? Can it help with that? The answer is a resounding yes! High-quality insulating foam ensures pests remain outside.

Ease of use

Some people would prefer to take the easier way out and install gaskets around the electrical outlet to keep out the draft. While this might be cheaper and less painstaking, applying an insulation seal offers a more permanent and effective solution. GE offers an easy-to-use option for sealing your home — spray foam. Shake the can, attach the trigger, remove the safety cap, and begin spraying.

Longevity

What’s worse than having to repair your outlet insulator? Having to do it twice. When choosing an electrical outlet insulation seal, you should select one that guarantees long-term results. The added flexibility of GE insulating foams and their chemical formula are all geared toward increasing the durability of the products.

Electrical outlet insulation is the first step toward realizing an energy-efficient home. An outlet insulator works in tandem with the wall’s insulation to maintain a steady indoor and outdoor temperature in your home. Choosing a suitable seal for the job is just as important as identifying the source of the drafts.

To find GE products near you, check out our Where to Buy page.

FAQs

Here are some frequently asked questions about electrical outlet insulation seals.

How do you stop cold air from entering through electrical outlets?

One effective way to stop cold air from entering through electrical outlets is to seal them with spray foam.

Do electrical outlet seals work?

Electrical outlet seals work, but the gasket may wear down over time or be inappropriate for the outlet. Applying a seal is the most effective way to keep out the draft.